Zogulitsa

Filimu Pulasitiki Yobwezeretsanso Shredder

● Palibe phokoso:Panthawi yophwanyidwa, phokoso likhoza kutsika mpaka 50 decibel, kuchepetsa kuipitsidwa kwa phokoso m'malo ogwirira ntchito.

●Zosavuta kuyeretsa:Chophwanyiracho chimakhala ndi mawonekedwe odulira ma diagonal ooneka ngati V komanso mawonekedwe otseguka, kupangitsa kuyeretsa kukhala kosavuta popanda ngodya zakufa.

●Zolimba Kwambiri:Moyo wautumiki wopanda zovuta utha kufikira zaka 5-20.

●Wosamalira chilengedwe:Imapulumutsa mphamvu, imachepetsa kugwiritsidwa ntchito, ndipo zinthu zomwe zimapangidwa zimakwaniritsa miyezo yapadziko lonse lapansi, ndikupangitsa kuti ikhale yogwirizana ndi chilengedwe.

●Kubwerera kwakukulu:Pali pafupifupi palibe pambuyo-malonda yokonza ndalama.

Single Shaft Plastic shredder

Mawonekedwe

1. Zothandiza kwambiri

Ili ndi luso lodula kwambiri, imapereka mphamvu yayikulu yometa ubweya, ndikuwonetsetsa kutulutsa kwakukulu.

2. Kukonza kosavuta

Masamba okhazikika amatha kusinthidwa kuti asunge kusiyana ndi Masamba Ozungulira. Sinthani mauna a skrini mosavuta.

3. Torque yayikulu:

Dual-speed hydraulic system, yokhala ndi chipangizo chozizirira mpweya. Kukankhira zinthu zosalala kuti zitsimikizire kuthamanga kofanana.

4. Chitetezo chapamwamba:

Bokosi lamagetsi lodziyimira palokha lokhazikika ndi Nokia PLC ndi zida zamagetsi.

Air-Cooled Industrial Chiller

● Kutentha kozizira ndi 7℃-35℃.

● Tanki yamadzi yosapanga dzimbiri yokhala ndi chipangizo choteteza kuzizira.

● Refrigerant imagwiritsa ntchito R22 yokhala ndi firiji yabwino.

● Dera la firiji limayendetsedwa ndi masiwichi apamwamba komanso otsika.

● Komprekita ndi mpope zili ndi chitetezo chochuluka.

● Imagwiritsa ntchito chowongolera kutentha chopangidwa ku Italy cholondola kwambiri cha 0.1℃.

● Zosavuta kugwiritsa ntchito, zomangidwa mophweka, komanso zosavuta kukonza.

● Pampu yotsika kwambiri ndi zipangizo zokhazikika, ndipo mapampu apakati kapena apamwamba amatha kusankhidwa mwachisawawa.

● Mutha kukhala ndi choyezera mulingo wa thanki yamadzi.

● Amagwiritsa ntchito kompresa mpukutu.

● Mpweya wozizira wa mafakitale wozizira umagwiritsa ntchito condenser yamtundu wa mbale yokhala ndi kutentha kwabwino kwambiri komanso kutulutsa kutentha mwachangu, ndipo simafuna madzi ozizira. Mukasinthidwa kukhala mtundu wa dera lachitetezo ku Europe, chitsanzocho chimatsatiridwa ndi "CE".

Zipangizo Zoyanika Zopangira Pulasitiki

● Kutentha mothamanga komanso ngakhale kutenthetsa bwino.

● Zokhala ndi chitetezo chowonjezera kutentha kwa chitetezo ndi kudalirika.

● Itha kukhala ndi chowerengera nthawi, chobwezeretsanso mpweya wotentha, ndi choyimira.

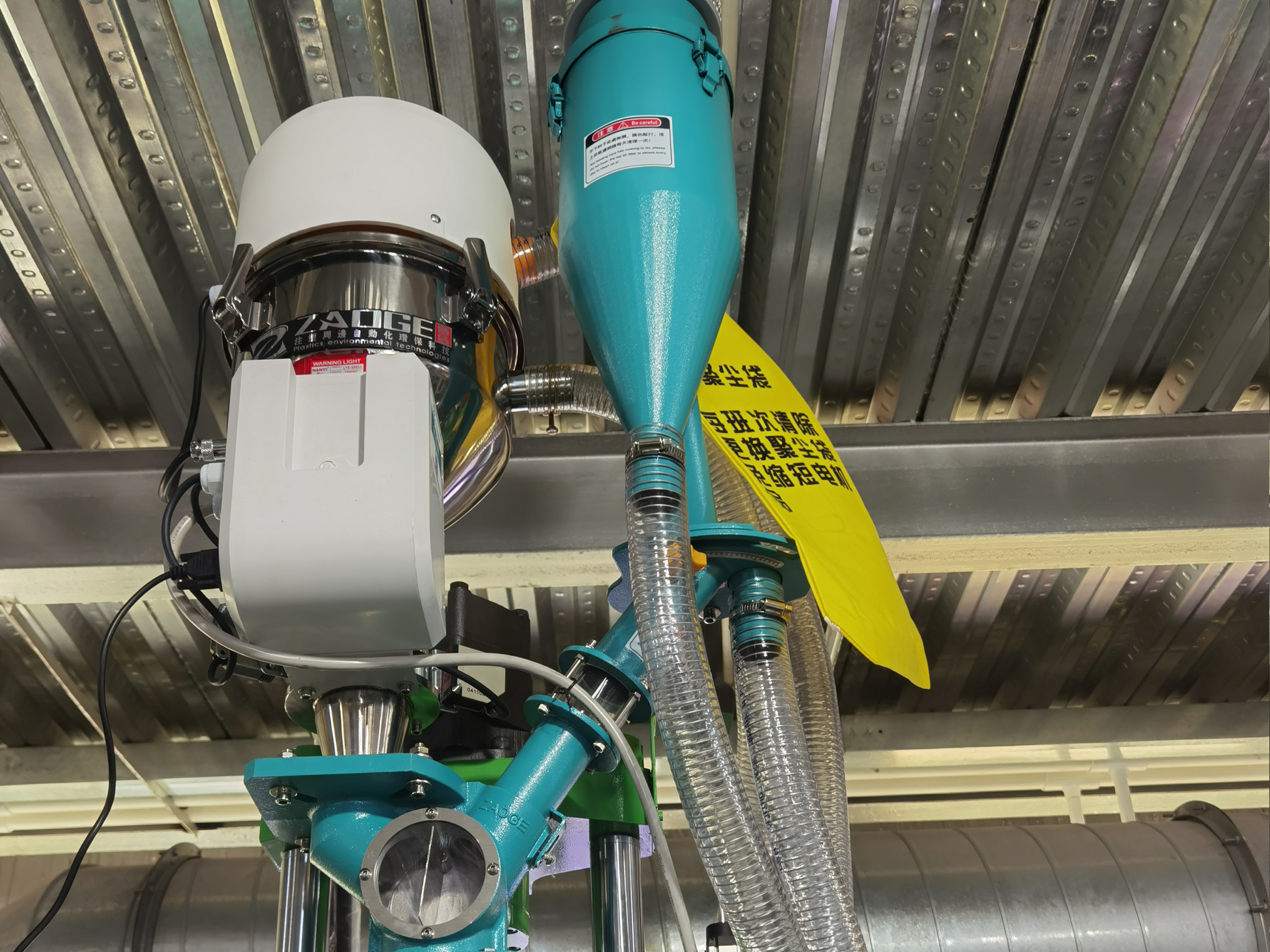

Ma Conveyor a Industrial Vacuum Ogulitsa

● Kukula kochepa, kosavuta kusuntha makina onse ndi osavuta kukhazikitsa;

● Wokhala ndi chowongolera mawaya kuti azigwira ntchito mosavuta;

● Imabwera ndi chitetezo cha injini, vuto la carbon brush ndi chikumbutso cha nthawi yogwiritsira ntchito;

● Hopper ndi maziko akhoza kusinthidwa mbali iliyonse;

● Wokhala ndi chosinthira chosiyanitsa komanso ntchito ya alarm yotsekera zosefera;

● Wokhala ndi chipangizo choyeretsera chodziwikiratu kuti achepetse pafupipafupi kuyeretsa pamanja.

Makina Otentha amtundu wa Mafuta a Mold

● Dongosolo lowongolera kutentha ndi digito kwathunthu ndipo limagwiritsa ntchito njira yoyendetsera magawo a PID, yomwe imatha kusunga kutentha kwa nkhungu kokhazikika ndi kulondola kwa kutentha kwa ± 1 ℃ m'malo aliwonse ogwirira ntchito.

● Makinawa amagwiritsa ntchito pampu yothamanga kwambiri komanso yotentha kwambiri yokhala ndi mphamvu komanso kukhazikika.

● Makinawa ali ndi zida zingapo zotetezera. Pakachitika vuto, makinawo amatha kuzindikira zachilendozo ndikuwonetsa vutolo ndi nyali yochenjeza.

● Machubu otenthetsera magetsi onse amapangidwa ndi zitsulo zosapanga dzimbiri.

● Kutentha kwanthawi zonse kwa makina amafuta amtundu wamafuta kumatha kufika 200 ℃.

● Mapangidwe apamwamba a dera amaonetsetsa kuti kutentha kwapamwamba sikuchitika ngati kulephera kwa kayendedwe ka mafuta.

● Maonekedwe a makinawo ndi okongola komanso owolowa manja, ndipo ndi osavuta kusokoneza ndi kukonza.

Water Mold Temperature Controller

● Kutengera makina a digito a PID omwe ali ndi magawo owongolera kutentha, kutentha kwa nkhungu kumatha kukhala kokhazikika pansi pa ntchito iliyonse, komanso kuwongolera kutentha kumatha kufika ± 1 ℃.

● Wokhala ndi zida zambiri zotetezera, makinawo amatha kuzindikira zolakwika ndikuwonetsa zovuta ndi magetsi owonetsera pamene kulephera kumachitika.

● Kuziziritsa kwachindunji komwe kumakhala kozizira kwambiri, komanso kokhala ndi chipangizo chongowonjezera madzi mwachindunji, chomwe chimatha kuzizira msanga mpaka kutentha komwe kwakhazikitsidwa.

● Mkati mwake amapangidwa ndi zitsulo zosapanga dzimbiri ndipo sizimaphulika chifukwa cha kupanikizika kwakukulu.

● Maonekedwe ake ndi okongola komanso owolowa manja, osavuta kuwachotsa, komanso osavuta kukonza.

Madzi Oziziritsa Mafakitale Ozizira

● Makinawa amatenga ma compressor apamwamba kwambiri ochokera kunja ndi mapampu amadzi, omwe ndi otetezeka, opanda phokoso, opulumutsa mphamvu, komanso olimba.

● Makinawa amagwiritsa ntchito chowongolera kutentha kwa makompyuta, ndi ntchito yosavuta komanso kuwongolera molondola kutentha kwa madzi mkati mwa ± 3 ℃ mpaka ± 5 ℃.

● Condenser ndi evaporator adapangidwa mwapadera kuti azitha kuyendetsa bwino kutentha.

● Makinawa ali ndi zinthu zodzitetezera monga chitetezo cha overcurrent, high and low voltage control, ndi zipangizo zamagetsi zochedwa nthawi. Pakavuta, imatulutsa alamu mwachangu ndikuwonetsa chomwe chalephereka.

● Makinawa ali ndi thanki yamadzi yosapanga dzimbiri yosapanga dzimbiri, yomwe ndi yosavuta kuyeretsa.

● Makinawa ali ndi reverse phase and under-voltage protection, komanso anti-freezing protection.

● The kopitilira muyeso-otsika kutentha mtundu madzi ozizira makina akhoza kufika pansi -15 ℃.

● Makina awa amadzi ozizira amatha kusinthidwa kuti asagwirizane ndi asidi ndi alkali.